Cold-Plate Liquid Cooling

While developing advanced cooling technology, compatibility is definitely something to consider. How do we improve cooling efficiency without making extensive changes to existing data centers? Wiwynn presents – Cold-Plate Liquid Cooling Technology

Advanced Cooling:

A seamless upgrade option

Improving Cooling Performance Keeping Existing Data Center Infrastructure

Increased Performance in Every Aspect

Power Density

Cold-plate cooling solutions increase the processor-wattage limitation of a data center, providing higher power density. On top of this, the solutions also change the infrastructure of a server. For example, air-cooling structural designs are often volume-heavy and can therefore be removed to allow for a more compact design within a server.

Low PUE

Cold-plate cooling solutions removes heat by using liquid cooling technology. Since the liquid is cooled elsewhere, a server room will therefore require less air conditioning, reducing power usage while increasing cooling effectiveness.

IT Operation Stability

Air cooling requires fans on high fan speed. Cold-plate cooling technology, on the other hand, lowers the fan speed, and consequentially lowers the vibrational frequency and dust. Under a more stable environment, the system can increase its lifespan.

Simple and Easy Maintenance

Maintenance for cold-plate servers is similar to that of air-cooling servers. Parts are easily serviceable and replaceable without extra maintenance efforts.

Anti-Noise/Vibration

Having significantly lower fan speed, the generated vibration and noise are also significantly reduced, giving maintenance personnel a safer and friendlier operation environment.

Operation Safety

With the advanced leakage detection and mechanical design, operation personnel are prevented from unexpected liquid cooling accidents, ensuring their safety.

How Wiwynn’s Cold-Plate Solution Works?

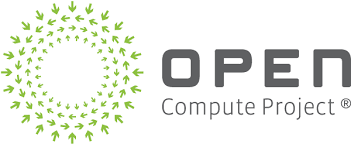

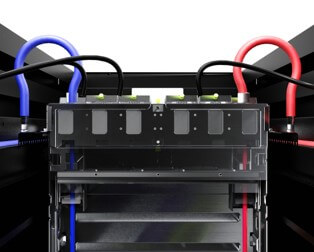

On the rack of each cold-plate server are two quick connectors (an inlet and an outlet). The cooling liquid enters the rack at its inlet and is directed to the cold plates. The cold plates are stationed at the processors (where most heat are generated) and other heat sources. The liquid heats up during the course and ultimately leaves the rack at the outlet.

When the liquid leaves the server, it is directed to the heat exchanger on the rear door of the rack. The fan wall operates to cool the liquid and a pump drives the cooled liquid back into the rack server for another full cycle of the heat exchange.

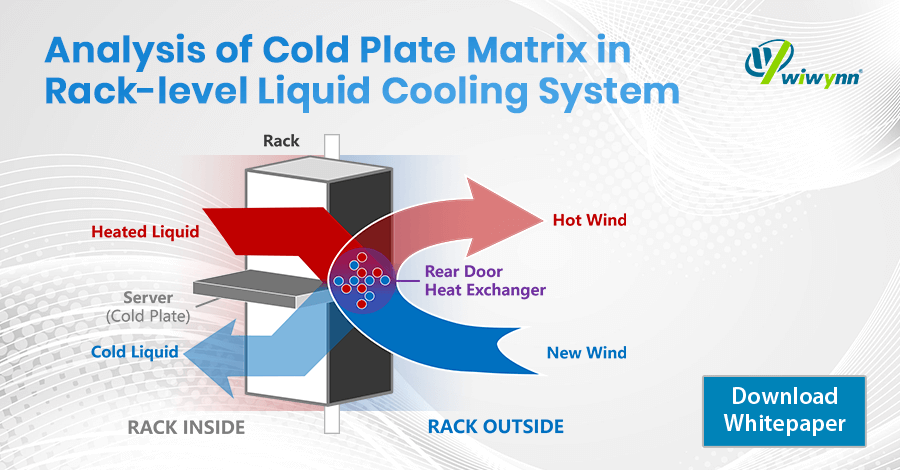

Wiwynn’s cold-plate cooling technology expands into multiple liquid cooling solutions. We can use water as the cooling liquid for one possible solution. Dielectric fluid can also be used for 2-phase design solutions. This allows us to take a step further into improving processing density as well as data centers’ safety requirements.

Multiple Innovative Design

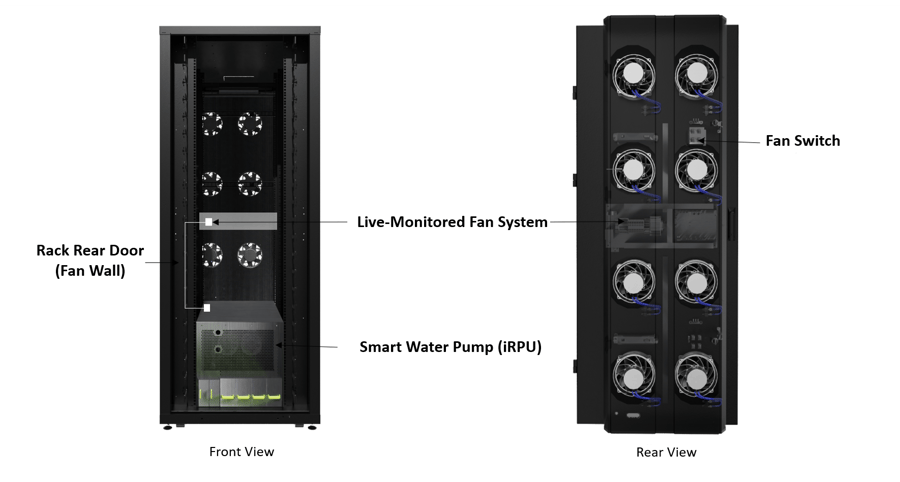

Live-Monitored Fan Wall System & Smart Water Pump (iRPU)

Wiwynn’s cold-plate design includes a fan wall for cooling the liquid. Data centers can easily implement this design without needing to change the infrastructure (e.g. hot aisle), allowing for quick and massive deployment into existing data centers.

Wiwynn’s smart RPU can monitor the liquid’s flow rate and fan speed. This dynamically adjusts cooling power usage to optimize power efficiency. On top of that, the fans have their individual on/off switch, where you can individually turn one fan off and replace it without affecting the operations of the remaining fans.

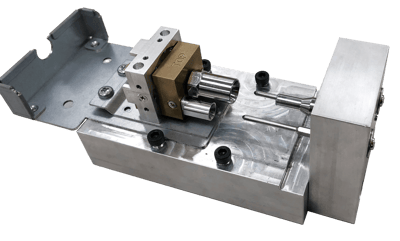

Blind-mate Liquid Cooling System with Internal Manifold

With Wiwynn's patented blind-mate module, the water loop connection can be completed when the liquid-cooled server is installed in the rack in the same way as the design of the DC-BUS BAR design, providing the same serviceability as the air-cooled server. At the same time, through the internal manifold design of the server, the coolant can be distributed to the chips in the server according to support the different requirements of different platforms.

Patented Blind-Mate Connector

Optimized Air Resistant Design

Wiwynn utilizes many exclusive design to ensure operation safety and cooling efficiency. The reliable blind-mate connector provides maintenance as easy as seen in an air cooling server. The floating design gives even more fault-tolerance, allowing simple and easy replacement.

Manifold tube routing design is also optimized for air flow. The pipes connecting the server has their curve minimized to lower the air resistance, which improves air flow while lowering power usage.

Highly integrated system BMC with comprehensive rack-mounted drip detection

Wiwynn’s detection integrated the server’s BMC with the rack (implemented with multiple sensors). The integration allows for the monitoring of pipes and connectors, and for the dynamic adjustment of liquid flow. Moreover, there is also an automatic circuit breaker mechanism to prevent accidents.

Partners

We would like to thank those that participated in the Open Compute Project – Rack & Power and the personnel involved in our advanced cooling project