Two-Phase Immersion Cooling

We provide an industry-leading cooling technology for the modern cloud applications, such as AI (Artificial Intelligence) and ML (Machines Learning). Wiwynn’s advanced cooling technologies cover a broad range of our lives.

The Next-Level Solution:

Saving 90% Cooling Energy

No extra power usage from fans and much less from air condition

Outstanding Power Density and Cooling Efficiency

Power Density

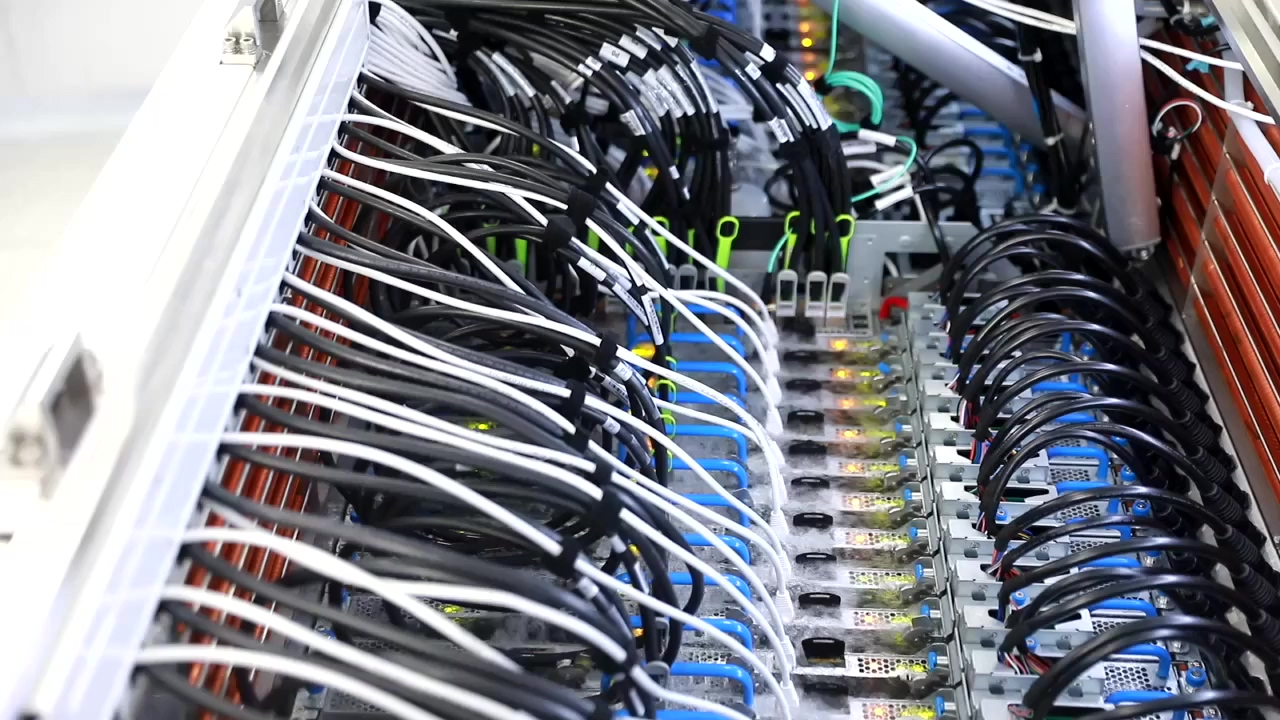

Tank-based two-phase immersion cooling requires no fans, the component deployment can be a lot closer, and heat dissipation is much faster from phase change of fluid. Cooling capability is therefore much better compare to air cooling to achieve higher power density.

Low PUE

Tank-based two-phase immersion cooling requires no extra power usage from fans and much less from air condition. This form of cooling is therefore much more power efficient compare to air cooling, where the majority of cooling energy expenditure in a data center comes from fans and air condition.

IT Gear Stability

Tank-based two-phase immersion cooling uses boiling liquid, and the liquid boils and transitions at a constant temperature. On the other hand, air cooling is affected by humidity, dust and other external environmental factors, which is in a more unstable environment compare to tank-based two-phase immersion cooling.

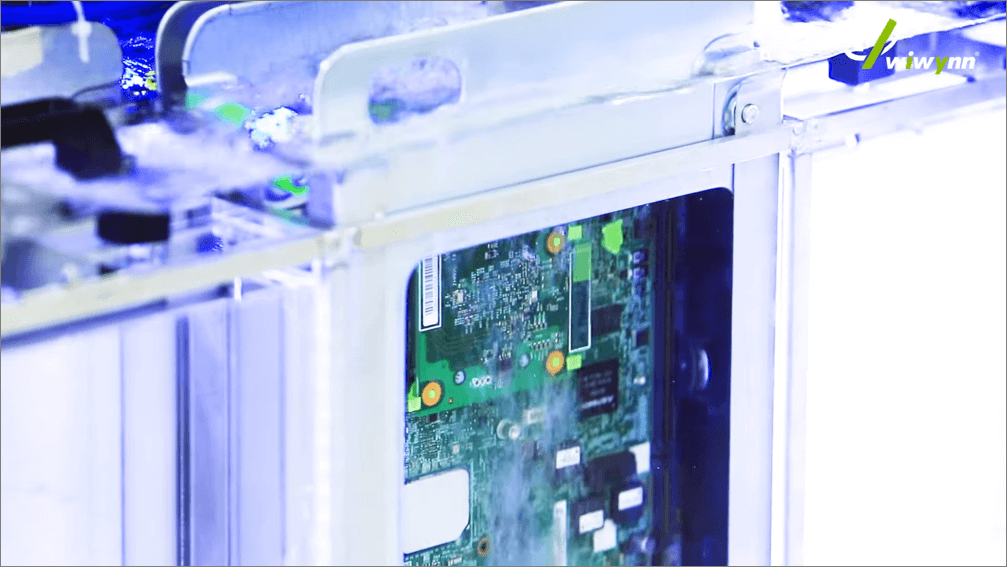

Easy Maintenance

Maintaining tank-based two-phase immersion cooling is a simple matter of removing the boards from the tank, taking away the time to drain the liquid as opposed to the maintenance of single-phase immersion cooling. Comparatively, air cooling solution maintenance is slightly more straight forward.

Anti-Noise/Vibration

IT operations under normal circumstances will provide a degree of vibration and noise, which will potentially affect the processors, hard drives, etc. For severe cases, they may also lower the system’s lifespan. In tank-based two-phase immersion cooling, the system is immersed in the liquid that greatly alleviates the impact of vibration and noise.

Operation Safety

Operators working on tank-based two-phase immersion cooling will need to wear gloves for safety as the inert liquid is kept at 50 degrees Celsius. On top of that, a good tank management system can also ensure the safety of the operator(s).

How Does Two-Phase Immersion Cooling System Work?

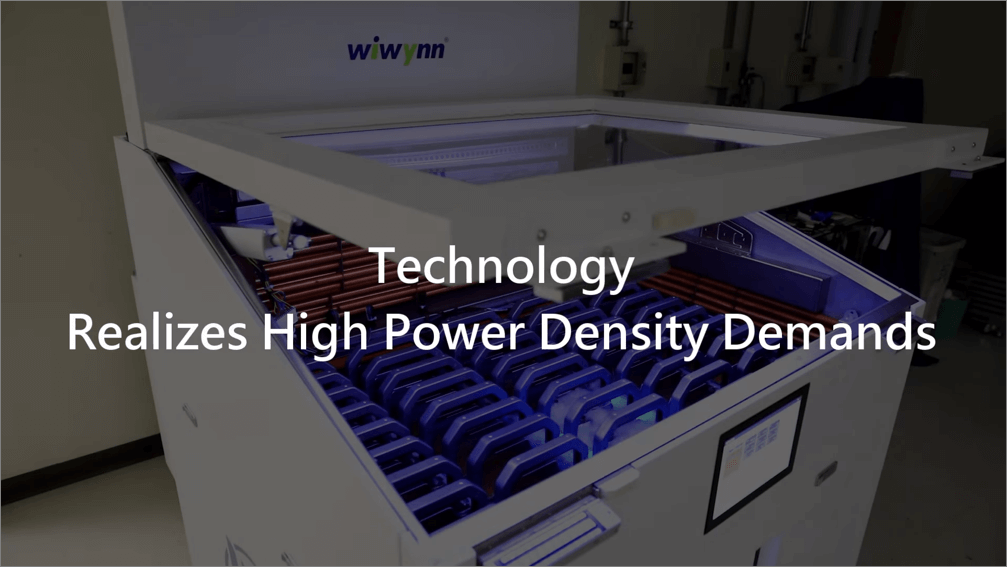

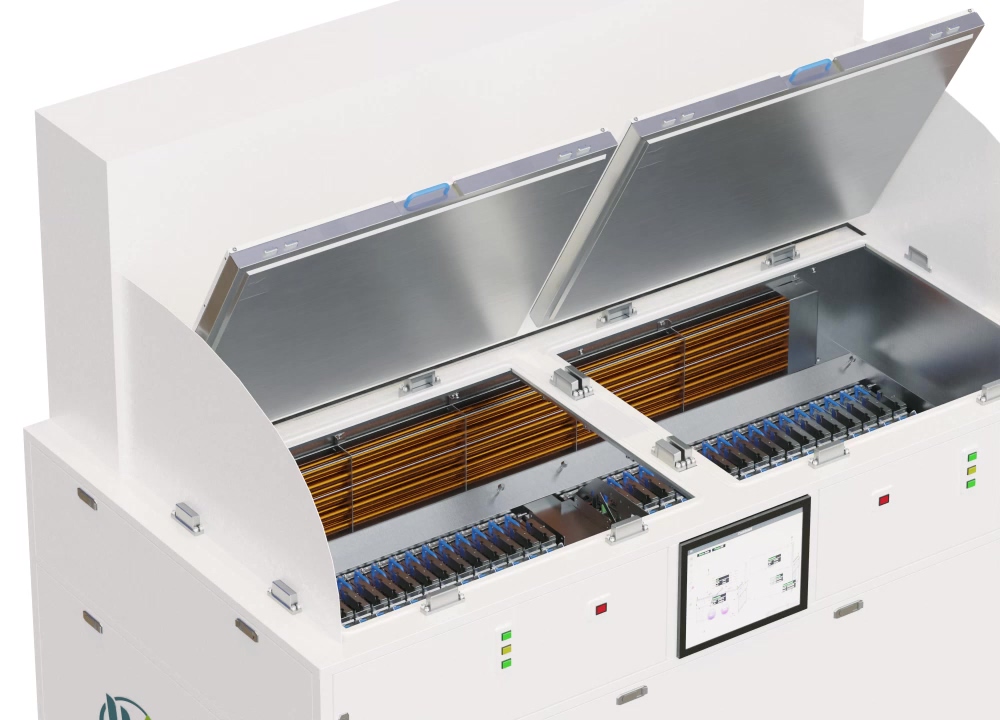

Introducing Immersion Cooling Tank. Powered by Wiwynn.

1. <1.01 partial PUE *1

2. Realize 2 times or more heat density *2

3. Lower 95% or more air conditioning requirement

4. The first two-phase immersion cooling solution deployed in cloud service provider’s hyper-scale production environment

*1 only includes tank and server power

*2 under the current server structure

The tank has a robust management system to monitor temperature, pressure, liquid level, etc.. The system then controls the immersion cooling system to achieve the best cooling and power efficiency.

The tank also has many safety protocols such as the anti-pinch design to protect the operator during the maintenance process.

Our Partners