2 min read

Autonomous AI Agent for End-to-End Component Data Extraction

1. Objective Streamline complex, error-prone manual data entry Reallocate engineering talent to high-value innovation Achieve end-to-end automation...

Press

Updated on July 26, 2024

Impedance matching in trace design may lead to problems such as signal reflections, crosstalk, and dissipation, which can affect the overall system performance and reliability. In design and manufacturing processes, characteristic impedance is prominent in even the slightest variations of any factors, which can deviate the intended impedance value, potentially resulting in unforeseen effects on the product.

Wiwynn conducted a series of experiments and analyzed various factors under proper process control. Based on the experimental results, it can be observed that the lateral etching amount of traces is influenced by copper spacing and thickness.

Register to Download the whitepaper!

2 min read

1. Objective Streamline complex, error-prone manual data entry Reallocate engineering talent to high-value innovation Achieve end-to-end automation...

1 min read

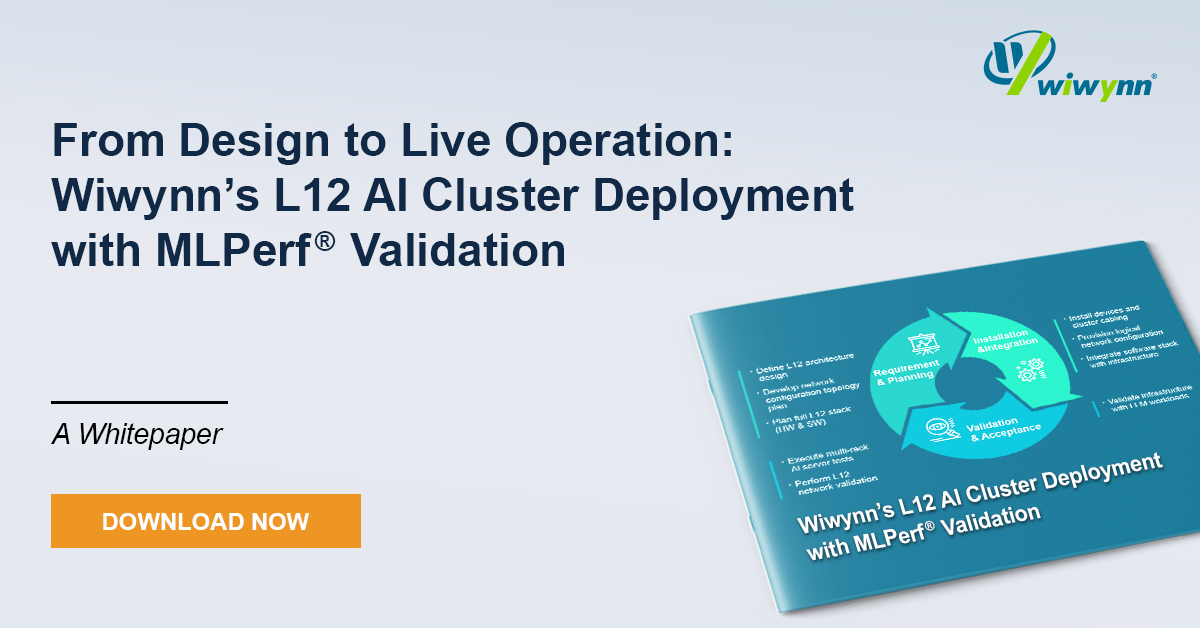

Deploying large-scale AI clusters introduces engineering challenges that extend well beyond the individual server rack. From liquid cooling...

1 min read

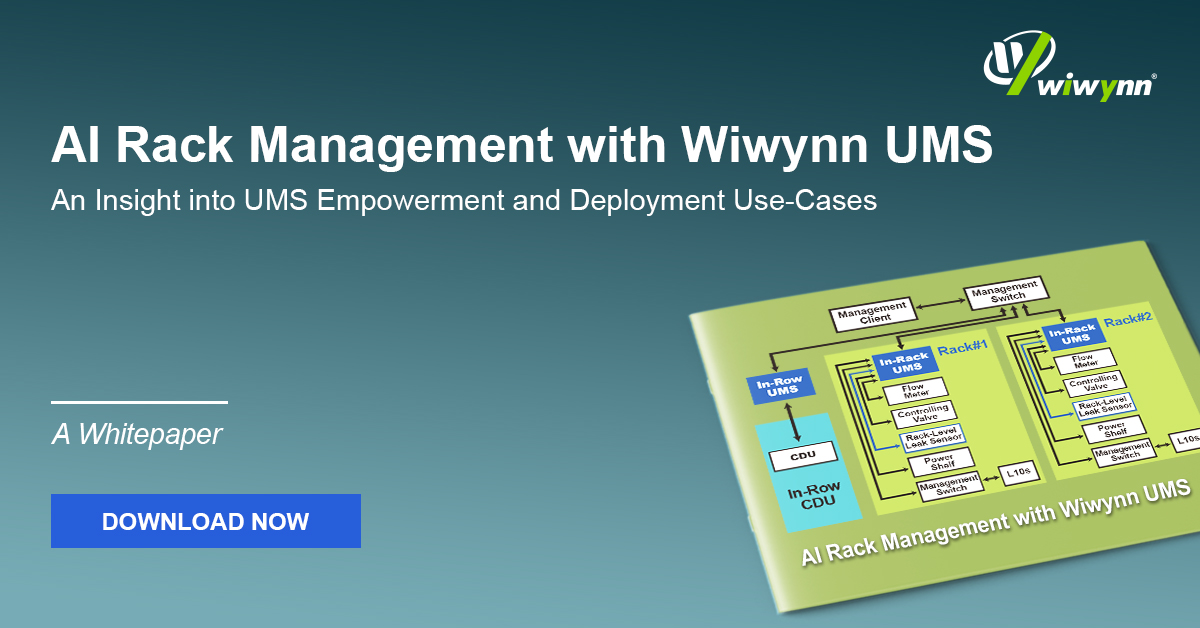

This paper discusses the rapid expansion of AI workloads and the resulting transformation in data center infrastructure requirements. Traditional...